Catalog

| No. item | Name of parameters | Result |

|---|---|---|

| 1 | Beryllium oxide content, % | 99,82 |

| 2 | Total oxide content (Ni, Fe, Ca, Si, Mg, Al, Zn, Cr), % | 0,18 |

| 3 | Apparent density, g/cm3 | 2,92 |

| 4 | Grain size, micron | 50 - 100 |

| 5 | Thermal conductivity in air, W/ (m � �) | 300,2 |

| 6 | Volume Resistivity, Ω x cm | 4,3x1016 |

| 7 | Dielectric permittivity at a frequency of 1 GHz | 7,261 |

| 8 | Dielectric dissipation factor at a frequency of 3 GHz | 2,087x10-4 |

| 9 | Breakdown voltage, kW/mm | 45,9 |

| 10 | Static bending strength, kgf/cm2 | 2092 |

Note: Standards for indicators of items 5-8 at a temperature 15-30 о С

Black ceramicunique development

High thermal conductive ceramic composites are indispensable in creating super high frequency absorptive materials with increased thermal conductivity, one of which components transmit super high frequency radiation while the other absorbs it. One such promising material from our company is a ceramic containing beryllium oxide and titanium dioxide. Produced volume absorbers of super high frequency energy have structural stability, homogenous electrophysical properties, and stability of properties over a wide range of temperature. As a result of sintering beryllium oxide ceramics with the addition of titanium dioxide micropowders in a reducing hydrogen environment, its density and electrical conductivity increase, and the ability to absorb electromagnetic radiation in a wide frequency range appears. The most effective material is the composition in which the mass content of titanium dioxide in beryllium oxide ceramic is 30%. This ceramic is named BT-30. The attenuation factor for super high frequency radiation passing through this ceramic composite (BeO + TiO2) in the frequency range of 8.5-12 GHz is 19-20 dB. Increasing the carbon content in the ceramic increases the electrical conductivity of this black ceramic.

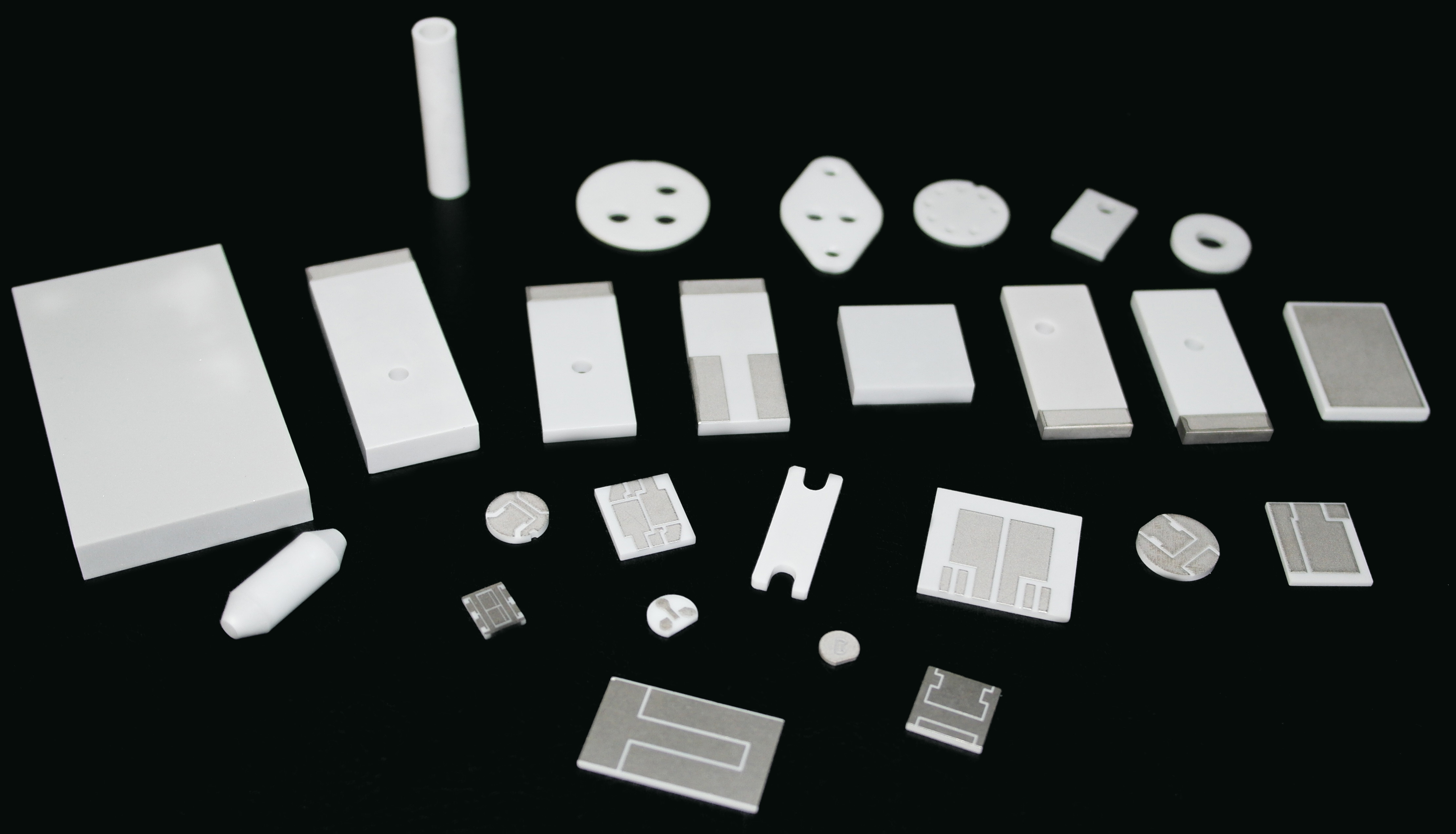

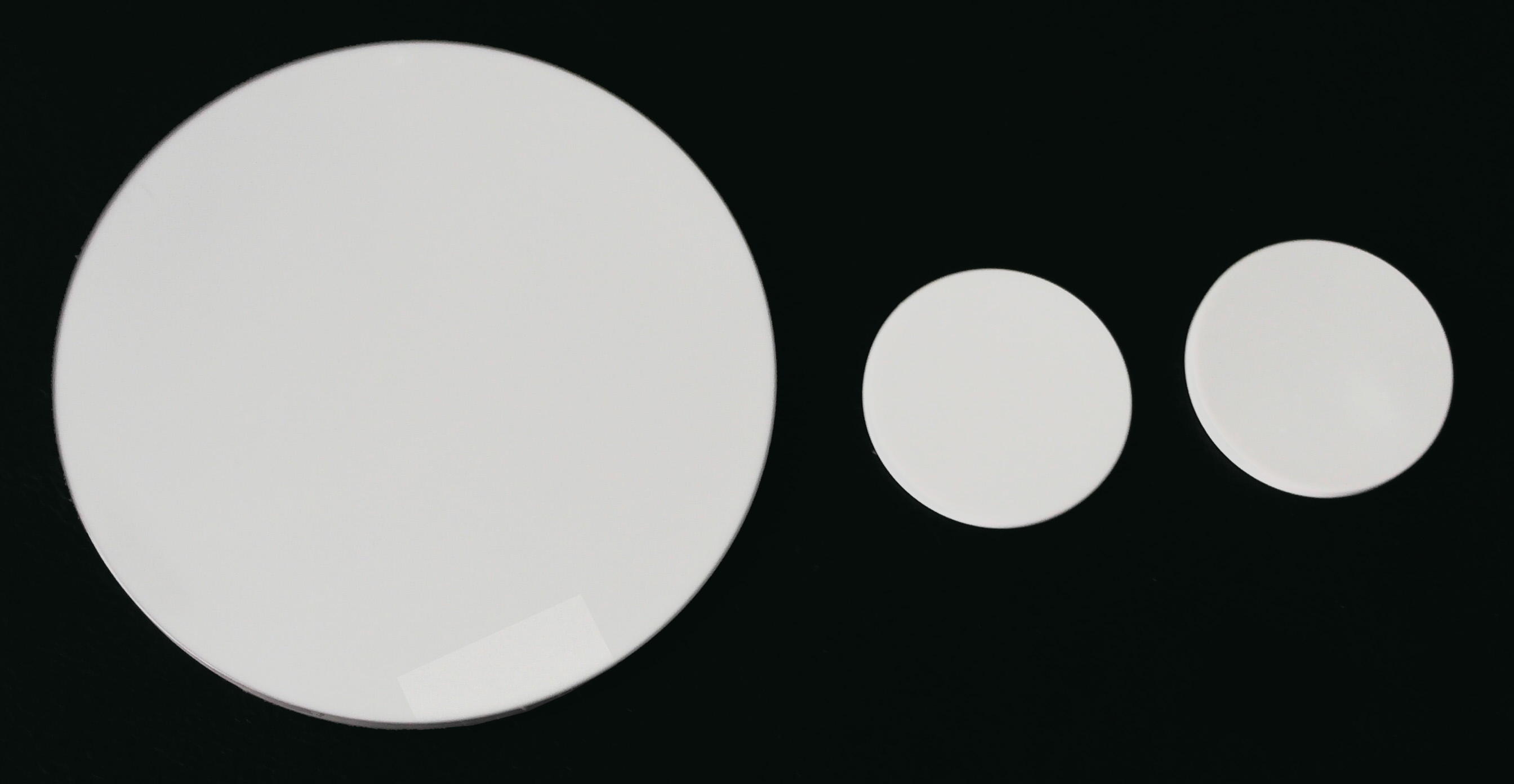

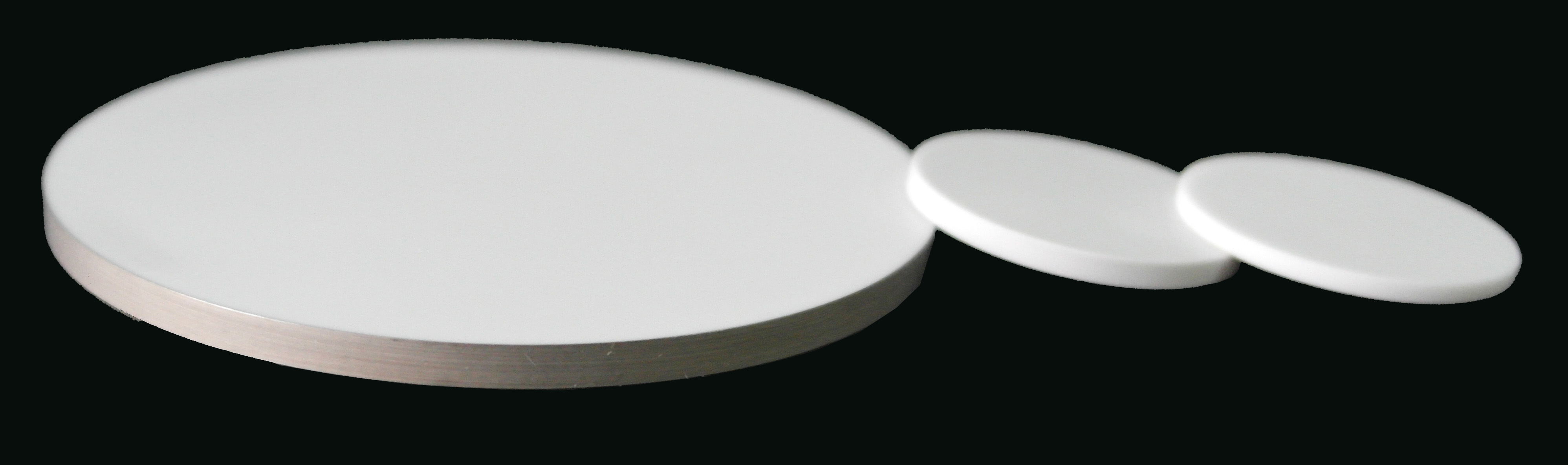

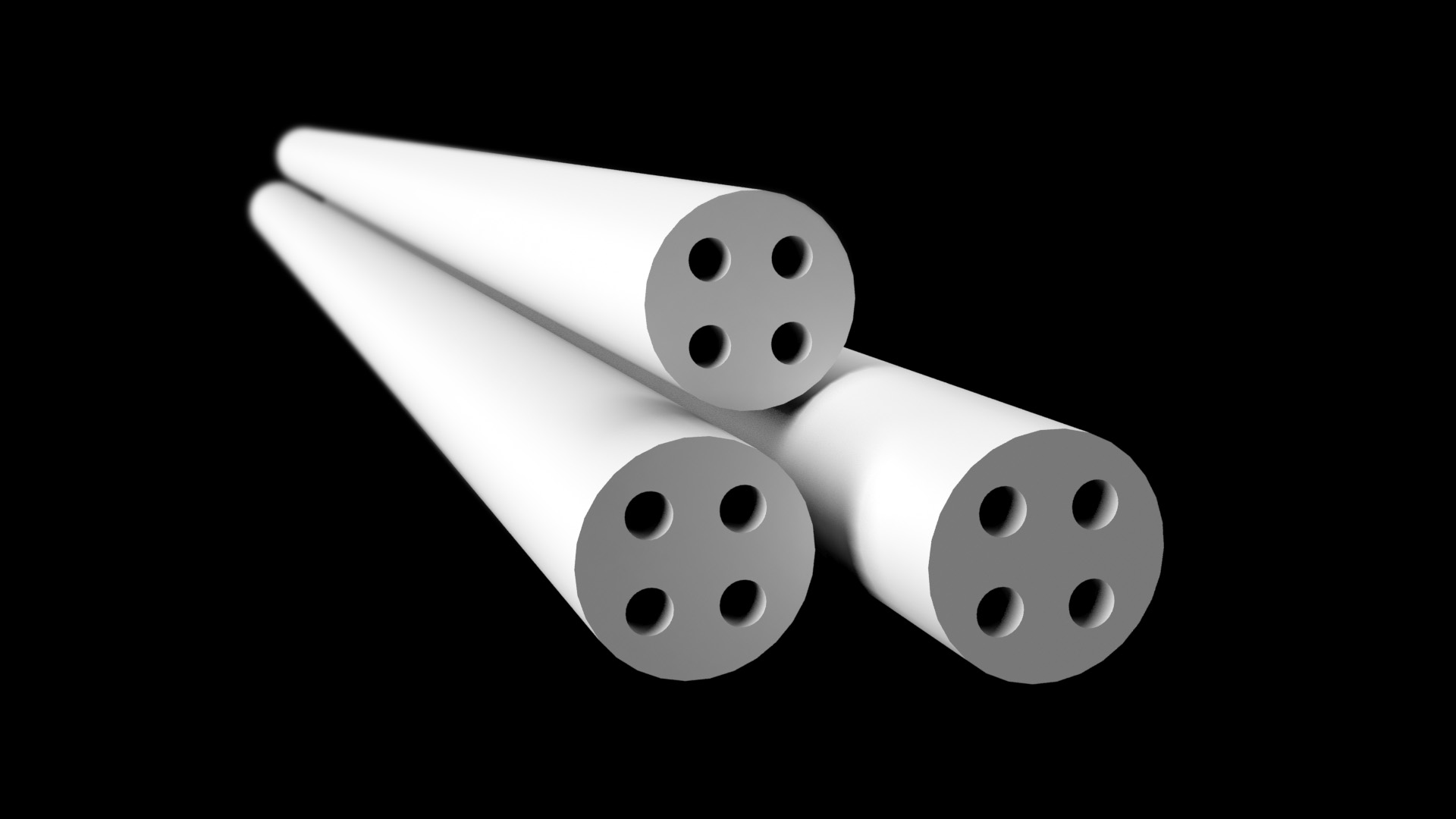

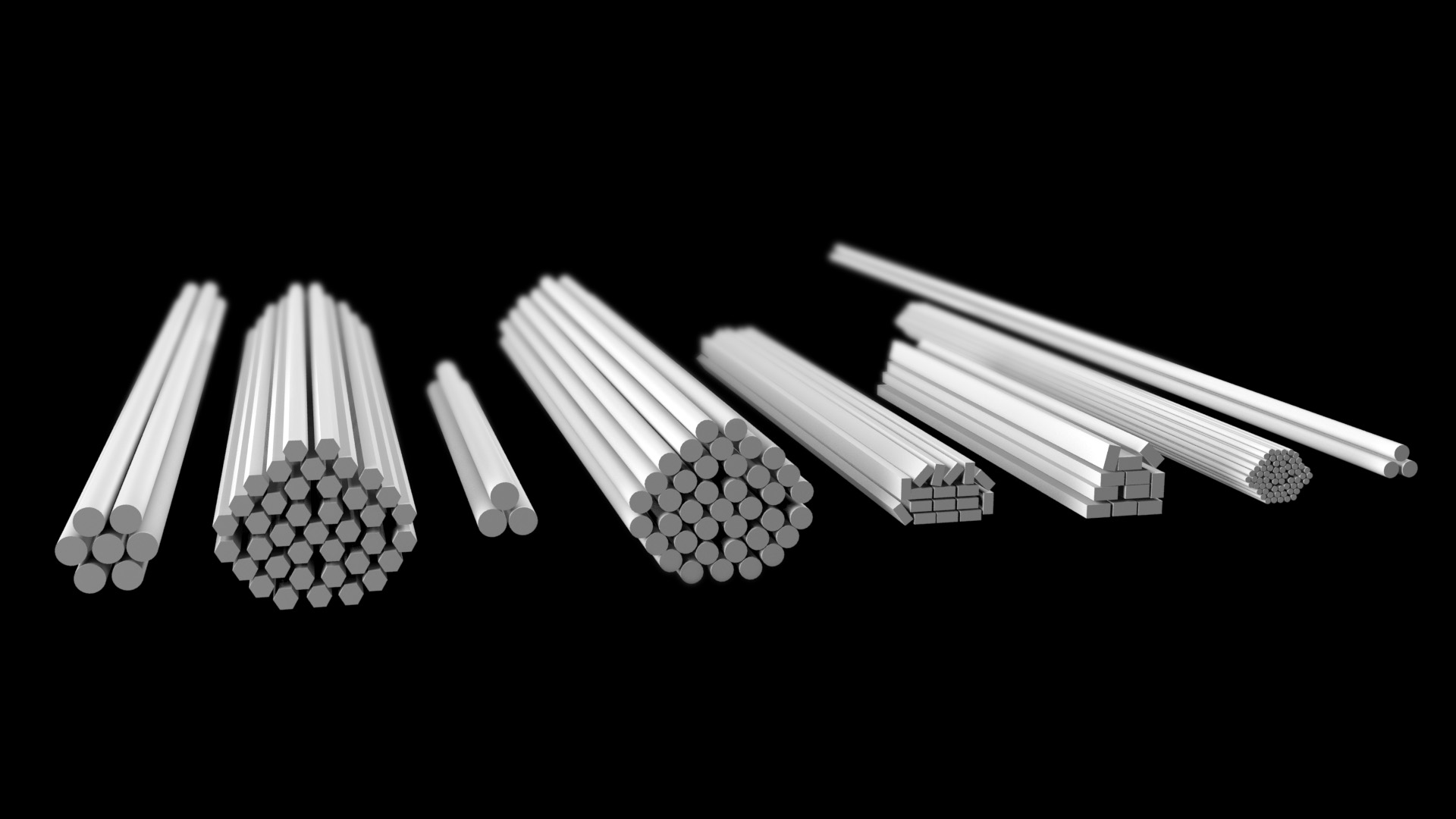

- Beryllium oxide profiles in finished form or semi-finished products, specifically designed for electronic components or as substrates for electronic circuits

- Beryllium oxide composite (BeO + TiO2) ceramic products